Industrial Robots

Robots, each deigned based on specific application. Some broad categories are

Industrial Robots

How to Choose Industrial Robots?

Industrial robots have become essential in manufacturing across the globe. Their efficiency, versatility, & production capabilities make them invaluable. But with so many different types available, how do you pick the right one for your business? The first step is to the main types of robots.

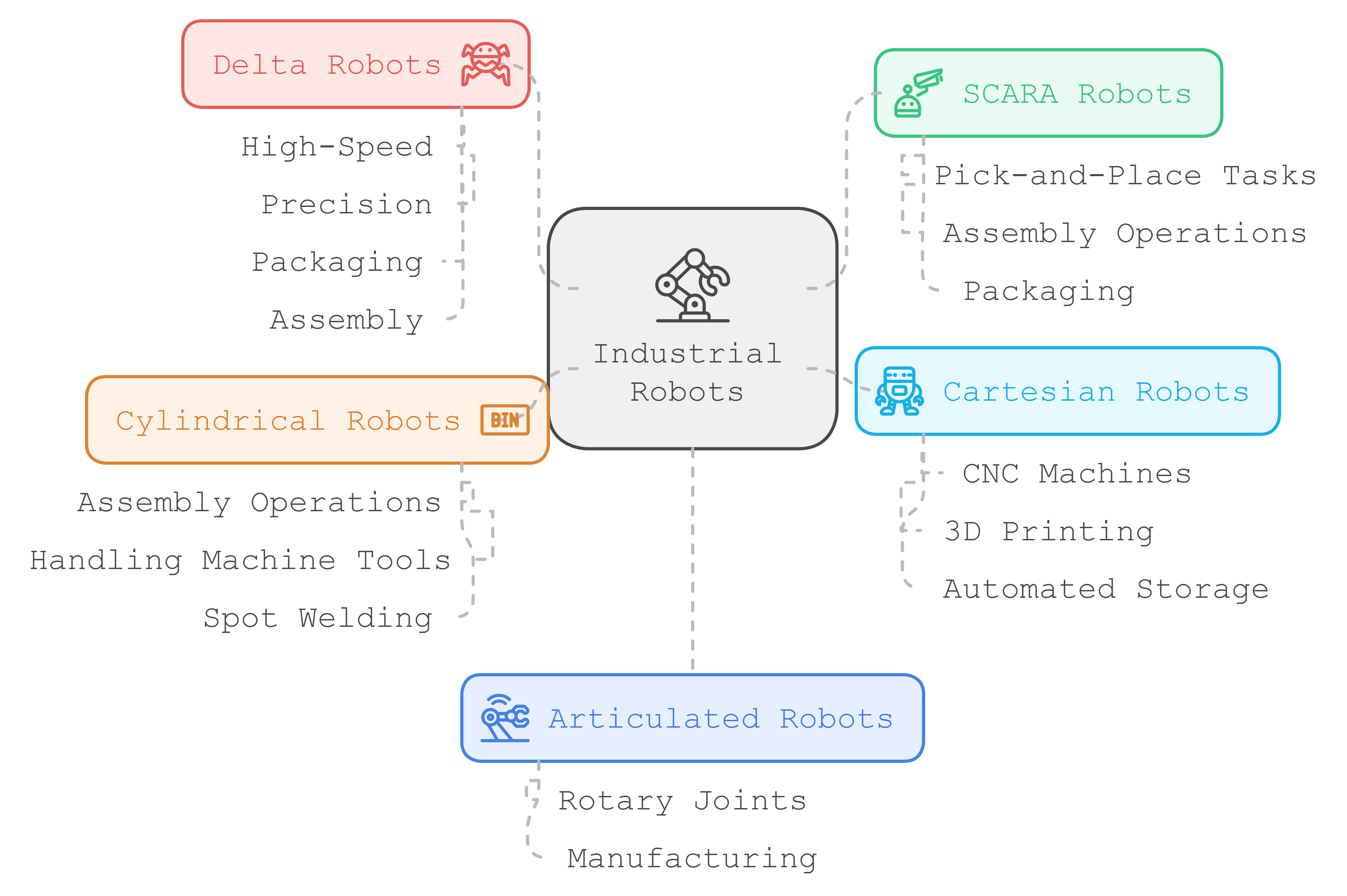

- Articulated Robots: The most common type is the articulated robot. has an arm that resembles a human's, with joints similar to an elbow, shoulder, or wrist. These robots are used mainly for printing, packaging, welding, machine tending, material handling, and metalwork. Equipped with rotary joints, these can range from simple two-jointed structures to intricate systems with ten or more interacting joints. They are typically used in manufacturing.

- SCARA Robots (Selective Compliance Articulated Robot Arm) are ideal for pick-and-place tasks, assembly operations, & packaging. They excel in high speed & precision. These all-in-one robots come with x, y, z, and rotary motion—everything you need in one package (excluding end-of-arm tooling). SCARA means Selective Compliance Assembly Robot Arm. They out their Speed and Accuracy With the ability to handle delicate assembly tasks flawlessly, design is more advanced than Cartesian and Cylindrical robots, enabling horizontal movements. The cost of these robots is mainly due to their precise components and the advanced technology required to ensure rapid yet delicate operations.

- Cartesian Robots: Also called gantry robots, possess three linear axes that move in straight lines. Commonly found in CNC machines, 3D printing, and automated storage systems. These robots have similar uses as articulated robots but are less expensive. They are highly customizable and easy to program. Customers can determine the stroke length, speeds, and precision because most parts arrive separately & are assembled by machine builders. The linear movements provide a cube-shaped workspace.

- Delta Robots: Recognizable by their spider-like appearance, these robots excel in speed & precision. They're ideal for high-speed pick-and-place tasks in packaging and assembly lines. Delta robots are the fastest around but also come with a hefty price tag. Featuring a unique dome-shaped work envelope, they achieve incredible speeds.Also called Parallel robots, these marvels stand out due to their distinct design and unmatched speed. Often utilized in food packaging and electronics assembly, they handle delicate items with remarkable precision. The cost? Influenced by specialized components & advanced control systems, providing the necessary technology to ensure high-speed accuracy.

- Cylindrical Robots: Features include at least one rotary joint at the base & one prismatic joint to connect the links. Utilized in assembly operations, handling machine tools, and spot welding.

How to Choose?

Picking the right robot for your needs can be tricky, but here's a guide to help:

Engineering Effort to maintain: Consider design, assembly & installation costs. They matter!

The consideration for Flexibility: Need five or six degrees of freedom? Maybe go for an articulated robot. If fewer axes are okay, a cheaper model could work just fine.

The need for Reach & Payload: Got lightweight stuff to move? A Cartesian robot might do the trick. For heavier things, you’ll want something different for better performance.

The timing & work unit Speed: If you need things done fast, think about using a Delta robot.

Overall Space & Footprint: Worried about space? Cartesian or Delta robots have smaller footprints, saving room on the factory floor.

Finally the reliability : Mechanical failures are a hassle. Pick models that are easy to troubleshoot and fix to keep downtime short.